Iron Phosphate vs. Lead-Acid: Where Electric Forklifts Are Going

Seven years ago, I looked into a newer forklift manufacturer that only sold forklifts with an Iron Phosphate battery.

This company had never built a forklift before. Yet in 2009, they built a factory to start building their own forklifts. Before that, the company had already built & sold electric buses, cars, and trucks across Europe and Asia for years.

They also controlled 50% of the world cellphone battery market, having started making lithium-ion batteries for Motorola in 1995.

I had a hunch that those batteries would change the future of our industry. I spent months working a deal to bring these forklifts to Northern California. You know them by now—they're the BYD electrics.

Now we're seeing movements in the electric forklift space. Movements that tell me my hunch was right.

Let me share what the future of electric forklifts will be.

Forklift Manufacturers Moving Away from Lead-Acid toward Lithium-Ion

Rechargeable lithium-ion batteries have existed for years. Jungheinrich's electrics use them, for example. We're seeing other forklift manufacturers move away from lead-acid toward lithium-ion: CAT, Mitsubishi, Doosan, Linde, Hyster/Yale, Toyota, Unicarrier, Crown, Raymond, and others.

Progress is slow, however. They're running into unfortunate snags:

- The industry still uses 36- or 48-volt for normal forklifts, vs. 80-volt. With lower volts, you get fewer kilowatt-hours.

- Only a few of these batteries have UL approval.

- Lithium-ion trucks usually have a limited warranty (e.g., 3 years) vs. a BYD 10-year warranty.

- In some cases, these manufacturers run into an unusual problem—the lithium-ion batteries are too light! A lithium-ion forklift battery weighs about 40-45% less than a lead-acid battery.

That means they have to add weight, like steel or cement, in the battery case. As a result, the KWH capacity is not good enough. The forklift doesn't have the kilowatt-hours to run for 1 full shift, let alone 2-3 shifts our industry needs now.

The Iron Phosphate Battery Wins Against Lead-Acid Every Time

While the lithium-ion effort is great and I hope it brings more success, the fact is that these manufacturers have already been outflanked. They're trying to create the battery of tomorrow—while the battery of 5 years from now already exists.

It's the Iron Phosphate Battery. These batteries beat everything else in the industry. They even beat lithium-ions, but let's compare them to lead-acid. That will show just how advanced the Iron Phosphate is.

- With a lead-acid, you’re lucky to get one shift before it needs charging again. Iron Phosphates will go 2-3 shifts on one charge.

- Charging a lead-acid battery? Better find another truck; it'll be stuck charging for 8+ hours. An Iron Phosphate goes from 0% to 100% in less than 90 minutes. If you had 3 shifts and charged during lunch, you can use the forklift 24/7.

- An Iron Phosphate charger will "fast charge" in 1 to 1.5 hours with no damage to the battery. Doing a "fast charge" with a lead-acid battery ends up cooking it – reducing its life span to 2 years on average!

- BYD warranties their Iron Phosphates for 10 years (or 20,000 hours). I've never seen a single lead-acid battery last near that long.

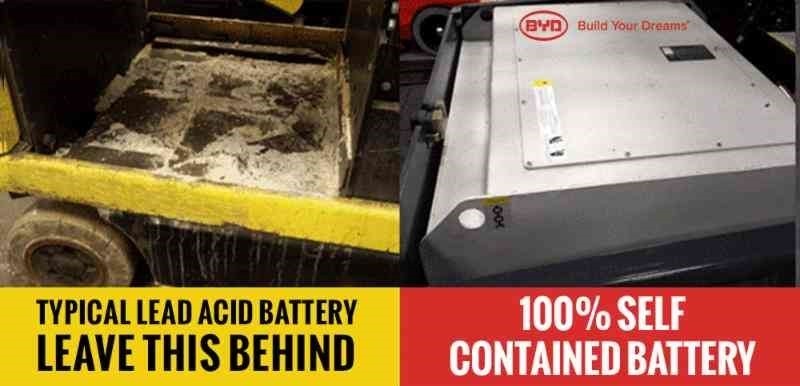

- Lead-acid batteries hurt the environment just by existing. They're toxic to the Earth and to your workers. An Iron Phosphate has no chemicals, no acids, and no gassing. It blows my mind, but these batteries are 100% environmentally friendly!

Here's a breakdown of the comparison. Good way to see where the future's heading.

Business Considerations: Comparing Lead-Acid to Iron Phosphate

|

| LEAD-ACID BATTERY | IRON PHOSPHATE BATTERY |

| Charging Infrastructure | Battery Rooms, Irrigation, Chargers | Opportunity Charging |

| Charging Time | 4-8 Hours | 1-1.5 Hours |

| Battery Maintenance | Battery Washing, Checks | Zero |

| Battery Life Span | 25% Failure Rate after 5 Years | 10+ Year Battery (World's longest battery warranty) |

| Operational Factors | Long Charge Time, Irrigating, Equalizing | Zero |

| Liability | Gassing, Venting, Corrosion, High Disposal Costs | Zero - Environmentally Safe Battery |

| Fire Safety | Can Catch Fire | No Risk |

| Dangerous Components | Heavy Metals, Toxic Chemicals | Zero |

| Risks to Workers | Burns, Fumes, Toxic Gas Exposure | Zero |

One Shift on Toxic Batteries is No Longer Enough. Iron Phosphate is the Future.

Our industry needs to increase running hours on electrics, across the board. One shift doesn't work anymore. We're in an age of 24-hour global distribution. Our forklifts have to measure up.

Is the Iron Phosphate forklift battery ready to replace lead-acid batteries? Yes. It's ready now. And from what my customers tell me, they're ready for a change, too.

If you'd like to try out an Iron Phosphate forklift, give us a call. We're happy to demo a BYD forklift for you.

Until next month!

Marshall Cromer, The Forklift Boss

Cromer Material Handling

Deal of the Month

TWO CAT P7000 LPG FORKLIFTS – $19,800 EACH!

For our Deal of the Month, we have two 2013 CAT P7000 forklifts. These are high-capacity trucks; each has a 7,000# capacity, and only about 4,300 hours on them.

For our Deal of the Month, we have two 2013 CAT P7000 forklifts. These are high-capacity trucks; each has a 7,000# capacity, and only about 4,300 hours on them.

They each have new solid pneumatic tires, a fresh coat of paint, and 48" forks with side-shifting fork positioners. We have one in our Oakland facility, and one in our Fresno facility.

The price? Only $19,800 each. This is an exclusive price for subscribers; you'll save thousands if you act fast!

To pick up one of these forklifts, call Cromer at 800.974.5438 and ask for the July Deal of the Month.