Are You Maximizing Your Trailer Space?

If Not, You're Throwing Money Away on Each Pallet

“The pallet is the unit that controls the world.”

That’s what I told a group of attendees at the Doosan Boot Camp in 2017. The boot camp ran from September 19-21 in Atlanta, with many of my fellow material handling professionals attending.

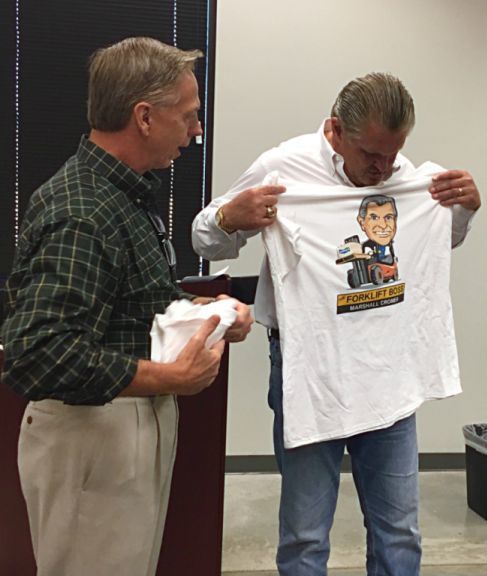

Doosan kindly gave me presentation time. (And a Forklift Boss t-shirt. It’s awesome!) While speaking, I challenged the attendees to tell me their average pallet weight. I offered $20 to anyone who could give me the correct weight amount.

Nobody won it.

Why is average pallet weight important? If you ship even a single truck of product out this holiday season (or ANY holiday season), you need to know the answer. Let's break it down. You'll see why.

How Many Pallets can You Fit in a 53-Foot Shipping Trailer?

There are three shipping trailer sizes in use today: 40-foot, 48-foot, and 53-foot. A standard GMA pallet is 48" long x 40" wide.

Some simple math tells us that a 53-foot trailer (which is 636” long) will fit 13 pallets lengthwise, with about 1 foot extra. These trailers are wide enough for two rows of pallets. So you’re looking at 26 pallets loaded into every 53-foot trailer.

What does this have to do with weight? Now that we know how many pallets we can add in, we can determine how much each needs to weigh. But there’s one more thing to take into account.

Are Your Shipping Trailers Full? If Not, They Cost You Money

Every time a shipping truck has to stop at a weigh station, they must meet certain state guidelines on gross weight. In California, shipping trucks cannot weigh over 80,000 pounds. (Some states go up to 84,500 pounds.)

But that’s the total weight. It includes the weight of the trailer itself, AND the truck pulling it!

That means we don’t have 80,000 pounds to work with for pallet weight. We have 80,000 pounds minus the weight of the truck & trailer.

By law, the truck & trailer cannot weigh more than 38,000 pounds. So we have...

80,000 pounds [gross weight] – 38,000 pounds [truck & trailer] =

42,000 pounds [max weight of product]

42,000 pounds to work with. Those 26 pallets need to weigh 42,000 pounds total. If they don’t, you’re not maximizing the trailer’s shipping value.

If we divide the product weight by the number of pallets determined earlier:

42,000 pounds [max product weight] / 26 [number of pallets in a 53-foot trailer] =

1,615 pounds per pallet

For a smaller container (40-foot):

42,000 pounds [max product weight] / 20 [number of pallets in a 40-foot trailer] =

2,100 pounds per pallet

Each pallet must carry 1,615 pounds in weight to maximize trailer space for 53-foot containers. If you have a 40-foot container, it’s 2,100 pounds per pallet.

This is what each pallet’s average weight should be.

Why are these numbers important? Consider what happens if a shipping truck pulls up to a weigh station, and it’s either over the gross weight, or under it.

OVER GROSS WEIGHT:

If either a trailer’s front or back axles are overloaded (above 34,000 pounds per double axle at the weigh station), then they have to rearrange the trailer’s contents. Right at the weigh station. The truck cannot leave until it’s below the max gross weight, and its axles are balanced.

If the truck must make its destination within a certain time frame, this can blow your delivery deadlines. You’re losing money for all the time the truck is stationary (and not traveling to its destination).

UNDER GROSS WEIGHT:

An under-loaded truck at a weigh station won’t have to deal with delays. But you’ll have less total profit from that shipment than you could have.

One or more pallets in the trailer are under-loaded. You could have shipped more product in the trailer. Which means you lost money by not filling each pallet to their average weight.

Maximize Your Trailer Space for Maximum Profit per Shipment

Now you know why I asked the Doosan boot camp attendees... "What is the average weight of YOUR pallets?"

Do you know yours? If not, you may be losing money on each & every pallet leaving the warehouse. What if you're leaving $200 in product behind with every load? $500? $1000?

Check your pallet weights using the math I've given here. Hopefully it helps you reach maximum profit!

For the equipment & pallet jacks needed to fit those pallets into your trucks, contact your local Cromer.

-Marshall Cromer, The Forklift Boss

Cromer Material Handling