15 Ways to Keep Your Rack Sturdy and Safe

Pop quiz: What's the most current safety standard manual for warehouse rack?

Answer: It's the "Considerations for the Planning and Use of Industrial Steel Storage Racks" Manual [2016 Edition], published By the Rack Manufacturers Institute.

Every warehouse manager needs to know & follow the safety guidelines it contains. But the manual's over 60 pages long...who has time to read all that?

So the Forklift Boss did it for you. I went through the entire manual, and extracted what I think are the 15 most important guidelines for safe rack setup. That's what we have for you today—a "Cliffs Notes" of ways to keep your warehouse's rack sturdy and your workers safe.

If you're not familiar with rack setup, let this serve as a quick introduction. If you're already familiar with rack setup, let this be a refresher for you.

Let's get started.

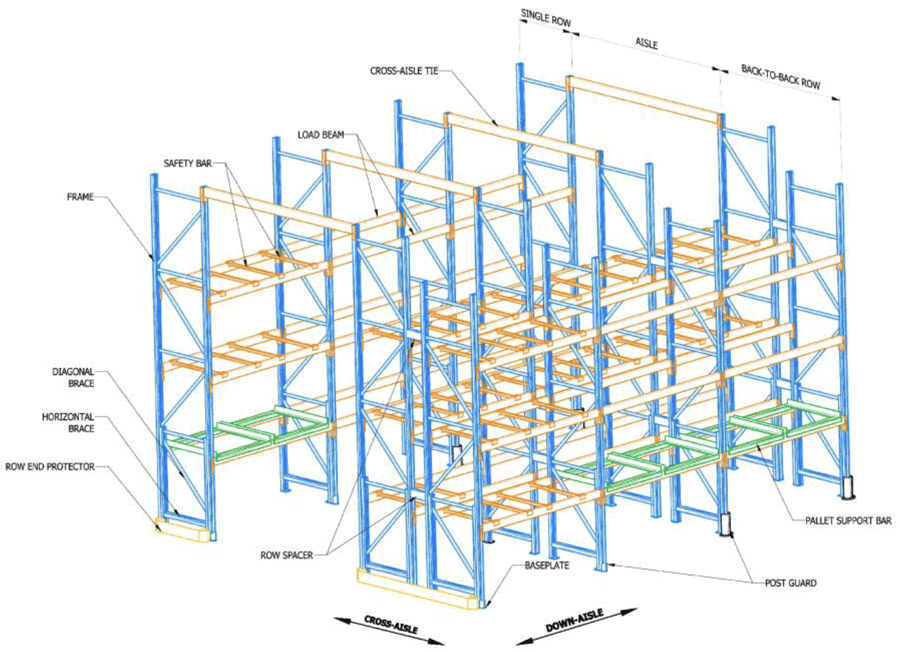

RACK SETUP/INSTALLATION GUIDELINES

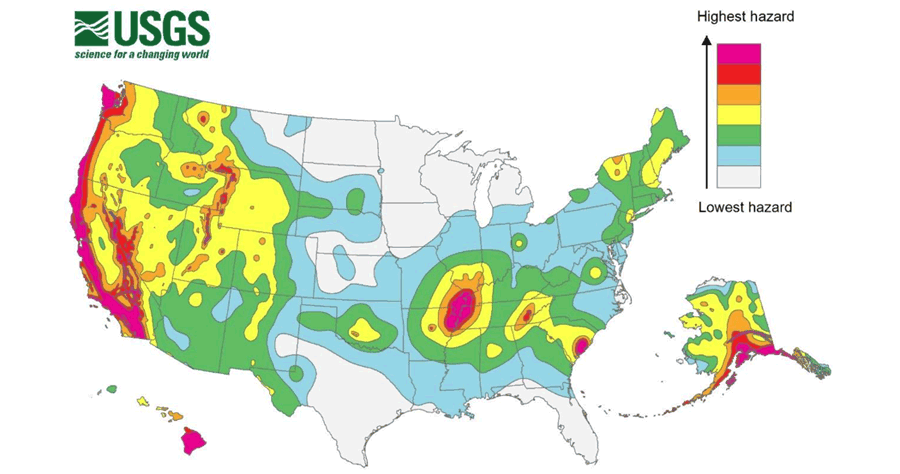

- Always plan around weather when designing your rack space. Earthquakes, wind, snow, rain/flooding, heat waves...all factor into stabilizing rack.

- Every rack setup plan should include: Forklifts used, required aisle width, max lift height on trucks, pallet/box load size & weight, bay width, rack type, egress, lighting, sprinkler requirements, & rack component specifications.

- Remember the permit before, and the CO after. Code permit for building the rack, and the Certificate of Occupancy when you've finished installing.

- Floor considerations: Floors should have a minimum of 5,000lbs concentrated load with a clear ceiling height of 15 feet. For every 5 feet over 15 above the top rack, add 2,500lbs to minimum load. (This is on a 4' x 8' floor grid.)

- Keep a safe egress. In most warehouses, the max egress (distance to an exit door from any point inside) is 400 feet with sprinklers installed, or 300 feet without sprinklers. If rack, forklifts, or other equipment prevent safe egress in this distance, you may need to partially redesign the warehouse layout.

- Adding new rack alongside existing rack? Test the attachment method with a warehouse design expert first! You should know the attachments will be compatible beforehand, or you're at risk of detachment & load collapse.

RACK SAFETY GUIDELINES

- Make sure your rack type will fully support the type of pallet you use. Wood, steel, and plastic pallets need certain rack types (drive-in, push-back, etc.). Example – If your rack uses a rail system, it won't have strong support in the middle. Plastic pallets may sag in the middle and cause product damage on these.

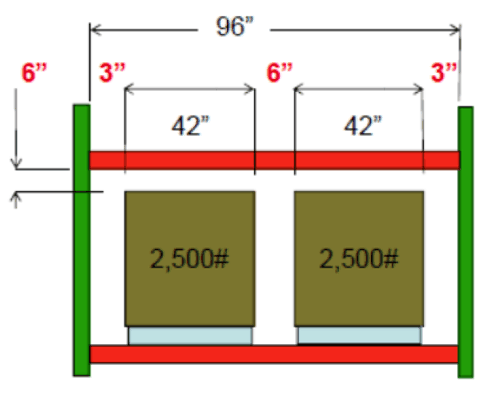

- Maintain good clearance around loads. Keep 6" between loads within a rack space, and 3" between each load & its rack column. Use tape or markers to ID so forklift operators can recognize clearance at a glance.

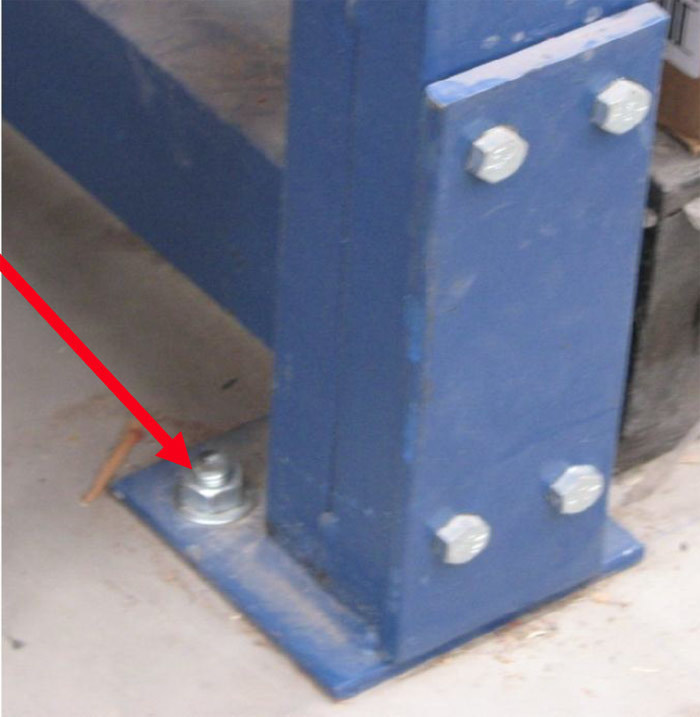

- Every rack column must have a bolt anchor to the floor. Inspect every anchor bolt when finished installing new rack.

- If you have painted rack, make sure it's in a safe indoor storage area! Exposure to outdoor weather or regular moisture may cause the paint to flake or chip. This is a toxic hazard if breathed in.

- Always buy rack that carries RMI Specification. If for no other reason than seismic safety. California is in the highest seismic risk zone in the US. With RMI-approved rack and a design expert, you'll know that all your racks will hold up during most earthquakes.

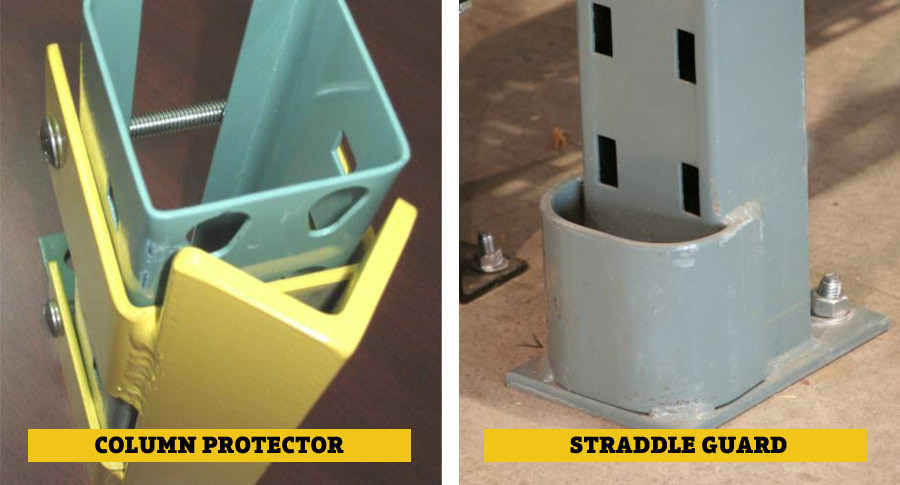

- Use straddle guards or column protectors on your racks. These prevent forklifts from accidentally running to & damaging rack columns at ground-level. You can attach protectors to the rack column, the floor beside it, or both.

LOAD SAFETY GUIDELINES

- Remember OSHA requires that all product stored on rack must be contained, or blocked to prevent it sliding off. (Load Containment/Confinement, Section 6.3)

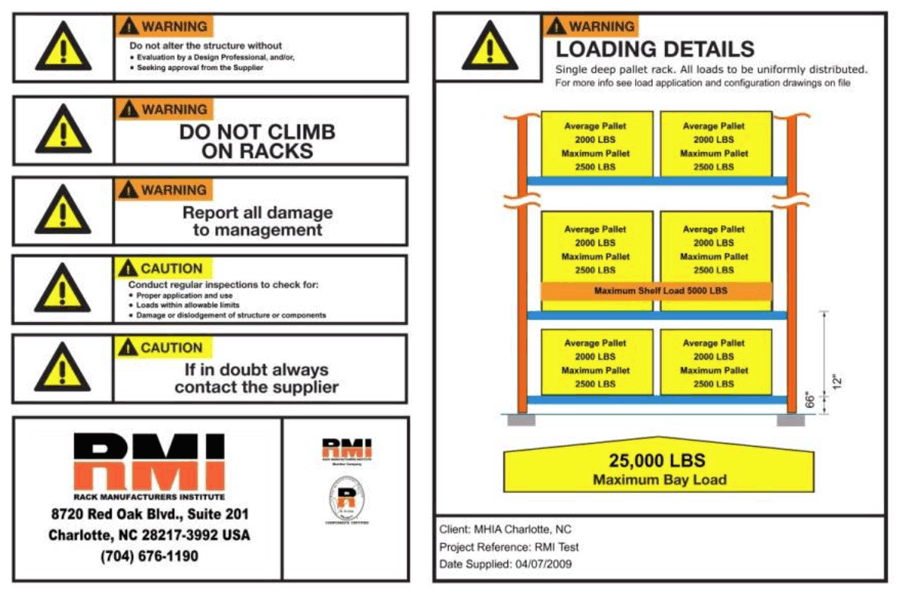

- Post load plaques to EVERY load shelf & the rack bay. These display the load limits & details, reminding all staff on safety. Here are some load plaque examples.

The rack supplier should stock these as well. - The #1 cause of rack failure is of course over-loading. The #2 cause is forklift impact. Guard against impacts by:

- Building sufficient clearance (horizontal & vertical) into each rack column.

- Training drivers on safe forklift operation.

- Use sufficient lighting on warehouse ceiling, floor, aisles, and on forklifts themselves.

- Impact protection devices, as I just mentioned.

Warehouse Safety is in the Planning

The RMI manual does have more information on rack specifications & material handling. If you want to read the full manual, it's available for purchase at: http://www.mhi.org/rmi

These guidelines illustrate the most important aspect of all rack setup – safe, sturdy construction & maintenance. Buy good-quality rack, put these guidelines into practice at your warehouse, and you’ll take one major worry off the plate.

Until next month!

Marshall Cromer, The Forklift Boss

Cromer Material Handling