Wear & Tear Signs for Forklift Tires

If you see a forklift tire missing a huge chunk or rubber, or a tire with a big blow-out on the side...you're going to replace that tire.

The question is, when does "normal wear & tear" produce a dangerous tire? Most tires don't have spectacular blow-outs; they wear slowly over time. Reacting to the conditions in your facility.

Your job is to keep an eye on those tires. Fortunately, regular checks on tires are easy. Wear & tear signs will show up right away, if you know what to look for.

How to Identify Wear & Tear…Before it Becomes a Big Problem

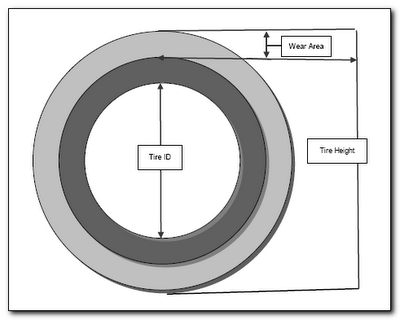

In 2014 we gave you the "Top of the Numbers" method in: How and When to Replace Forklift Tires Safely.

"On cushion tires, there’s a rule of thumb: “To the top of the numbers”. Each tire has a set of size numbers on it. For example, if you see “21x7x15” then you know it’s a 21-inch tire. Through use, the tire’s rubber wears down until the top of its surface touches these numbers."

"On solid pneumatic tires, you’ll find a wear ring or band. When wear & tear reaches this ring, then it’s time to replace the tire."

However, these aren't the only wear & tear signs you can watch for. Let me share 4 more.

Flat Spots

A flat spot means the tires have repeatedly worn down at one place in their routine. Frequent sharp turns under heavy loads can cause this. But if you see flat spots on more than one forklift's tires, you have an uneven spot in your warehouse floor.

Skid Marks/Balding

The tire is over- or under-inflated. This affects stopping power, forcing operators to jam on the brakes over & over. Not only does this hurt the tire, it can hurt the brakes!

Cracking

Cracking/chunking occurs from running over debris. I've also seen many tires crack due to temperature swings. Years back a customer's employees repeatedly drove a forklift past an open freezer on the left side. The forklift's left tires eventually cracked (even though the right-side tires were fine).

Oil/Grease Stains

An operator has driven the forklift through an oil spot or grease spill. Not only does this affect control of the forklift, the chemicals in oil & grease can eat away the tire rubber.

Spotting Wear & Tear Early Keeps Operators and Other Personnel Safe

These signs typically show up earlier than wear to the top of the numbers/wear ring. Which means they may help you prevent accidents well before any arise.

80% of tires are the same on every forklift. So don't discount one sign because "your tires don't do that." They might!

How do you avoid wear & tear like this? Good maintenance and regular clean-up. Specifically, things like:

- Keep Forklifts Well-Maintained. Preventative Maintenance not only extends forklift lifespan; it keeps their tires clean & properly inflated.

- Have Forklift Operators Check Their Tires Weekly. I know customers who check their tires on Mondays; others do it on Fridays. Whichever works best for you.

- Sweep Your Floors. Even built-up dust can cause problems, if your forklift tires are over-inflated and prone to skidding.

Time to Replace Old Forklift Tires? Call Cromer

Replacing forklift tires is a cheap & quick way to preserve forklifts (and their operators). That's why we're running a special on forklift tire replacements: 15% OFF on Tires, from now until May 31.

Click to Email Cromer for Forklift Tire Discount

All Cromer locations have a tire trailer with a 250-ton hydraulic press. Tire replacement takes less than 30 minutes on average. (Note: Delivery & recycling fee extra)

Remember, we will not replace only one tire on a forklift. It's unsafe. If one tire is worn down, chances are the other one needs replacement too (even if it looks OK).

Until next month!

Marshall Cromer, The Forklift Boss

Cromer Material Handling