6 Places a Dock Light Improves Warehouse Operations

The other day, one of our managers visited a customer’s warehouse. He saw a safety risk in the warehouse's operations, and an opportunity for improving efficiency, all by adding one simple item: A dock light.

While next to the warehouse’s loading docks, he saw a forklift operator using a flashlight to look into a backed up trailer. They did have one dock light mounted on the interior of the dock’s frame, but it couldn't shine into the trailer.

Of course, he pointed this out to the supervisor. They agreed to add a dock light, and our manager arranged for us to install one that same day. Only a few days later, he got a call from the supervisor, saying everyone appreciated the additional light.

Do You Need Dock Lights?

We often underestimate just how important lighting is. Until there’s an accident.

Take a stroll around the warehouse. Do you see any of these signs?

- Workers squinting/leaning their head closer to something

- Damage to docks from improperly-aligned trailers

- Forklift operators carrying flashlights

- Dock loaders/unloaders carrying flashlights

- Forklifts bumping into pallets or shelves

If so, your workers need more light.

Dock lights serve to illuminate not only a dock. They’re good for inside trailers, around corners, and in safety-conscious areas too. Let’s go through 6 ways you can use dock lights in the warehouse, as well as what kind of efficiency improvements to expect.

6 Places to Mount Dock Lights (and the Efficiency Improvements They Yield)

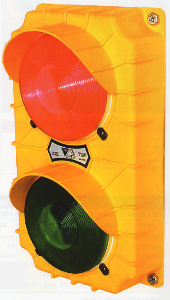

1. Outside the Dock/on the Building Exterior (Stop & Go Lights)

PURPOSE – Just like their city-road counterparts, these lights help the drivers guide their trailers back into the dock.

EFFICIENCY IMPROVEMENT – Regulates traffic, and reduces risk of dock damage.

2. Inside the Dock (On a Flexible Arm)

PURPOSE – Illuminates the inside of a trailer, at any height workers need.

EFFICIENCY IMPROVEMENT – When going through a dock, you’re passing through different light levels.

Warehouse → Dock Frame → Trailer Interior

If the trailer interior has poor lighting and you’re driving a forklift into it? You could easily have trouble seeing for 1-2 seconds. Two seconds is long enough to hit a co-worker or crash into pallets.

3. Inside the Dock (On a Swing/Strut Arm)

PURPOSE – Illuminates the inside of a trailer, and helps with paperwork.

EFFICIENCY IMPROVEMENT – Yes, this can speed up paperwork! Sometimes people will set up a small workstation next to the docks, and use the dock lights to complete their paperwork.

4. Outside Secure-Access Entryways (Stop & Go Lights)

PURPOSE – Identifies when it’s safe to enter (green) or when the entryway is closed/in use (red).

EFFICIENCY IMPROVEMENT – Protects against unauthorized access, and keeps safety regulations enforced (especially where hazardous materials are contained).

5. Above Blind Corners/Turns (Heavy Duty LED Lamps)

PURPOSE – Illuminates workers & forklifts turning around the corner.

EFFICIENCY IMPROVEMENT – Worker Safety. Others can see the shadows and movement, warning them about rounding the corner (and risking an accident).

6. Above Frequently-Trafficked Areas (Not Already Well-Lit)

PURPOSE – Extra lighting to make navigating a busy area clearer for everyone.

EFFICIENCY IMPROVEMENT – The simplest and most important reason of all...better lighting makes everyone safer while going about their work.

Boost Your Warehouse Efficiency with Dock Lights—Keep Everyone Safe and Productive

We’re seeing more activity from OSHA lately. More OSHA inspections, USDA inspections, and more oversight into corporate safety in general.

Worker safety, product integrity, avoiding any OSHA issues...it pays to be safe and productive! Dock lights are just one part of the successful warehouse. But they’re important when it comes to safety AND productivity.

Until next month!

Marshall Cromer, The Forklift Boss

Cromer Material Handling